Front End Loader: Safe Weigh System

Front End Loader: Safe Weigh System : Ask for Price

Low Cost Install And Purchase Price. User-Friendly Intuitive Four-Button Functionality

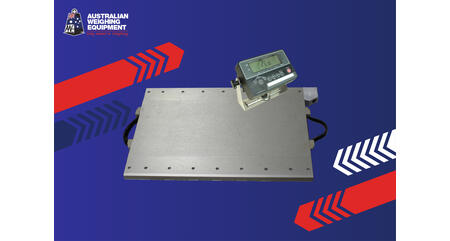

The 'SAFE WEIGH' instrument is our entry-level digital solution for onboard weighing. It has a low purchase price but the measuring system and reliability of the 'Safe Weigh' is identical to that of our premium 'Weight Master' series.

The 'Safe Weigh' displays the weight reading of any lifted load on an easy-to-read backlit LCD screen, and its intuitive four-button functionality make this unit an operator-friendly choice. It supports peripheral devices such as printers and alarms so you can customise your weighing system to better suit your applications. You can rely on the 'Safe Weigh' to perform reliably and accurately on your forklifts, reach trucks, walkie stackers and side loaders.

FEATURES:

- ±1% accuracy of machine capacity

- 9VDC to 70VDC power supply

- No loss of lifting capability

- Rubber-mounted bracket

- Rugged electronic design

- Custom heavy-duty case

- Australian design & manufactured

- Easy change-over from one machine to another

- Low cost installation and purchase price

- Digital LCD display with backlight

- High-accuracy temperature compensated pressure transducers

BENEFITS:

- Improved safety

- Increased business efficiency

- Eliminate overload fines

- Avoid under/over loading trucks

- Reduce trips to the weighbridge

- Check incoming/outgoing goods

- Prevent machinery and racking overload

HOW THE SAFE WEIGH WORKS:

The 'Safe Weigh' instrument produces a weight reading via a pressure transducer that is fitted to the hydraulic lines of your machine. The pressure transducer has a sensing element which responds to force applied by the hydraulic fluid pressure when a load is lifted. The 'Safe Weigh' instrument displays this reading on the display for the operators reference.

ADD-ONS:

PRINTER AND ALARM OPTIONS:

AWE offers a range of additional accessories which can be paired with the Safe Weigh instrument. These accessories

help customise your scale to better suit your workplace applications. Our safety accessories are a great solution to

prevent machinery overloading by operators - an event which can have serious consequences to machinery and operators.

- Blue Tongue 2.0 Printer: Produce hard copies of your weight readings with this compact printer. Comes with a swivel mount allowing easy mounting in your cabin. It is hardwired to your machine so no need to ever change batteries.

- Hydraulic Bypass: The ultimate safeguard against overloading you forklift. When a lifted load exceeds the forklifts capacity, the forklift will stop lifting - only allowing the load to be lowered. The capacity ratings are adjusted based on load centre principles.

- Red Light / Overload Alarm: A red light and/or audible alarm can be fitted to your scale as an extra safety device. These features are activated when the forklift exceeds the safe working load to alert an operator.

SPECIFICATIONS:

Type: Digital with microprocessor control

Applications: Suitable for most forklifts, reach trucks, walkie stackers, side loaders

Accuracy: ±1% of capacity (e.g. If lift capacity is 1000kg then accuracy is ±10 kg)

Dimension (mm):

- 260 (W) x 140 (H) x 90 (D) including bracket

- 215 (W) x 106 (H) x 90 (D) instrument only

Resolution:

-1

-2

-5

-10

-20

-50

-100

-200 (selectable to suit installation)

Temperature: 0°C to 40°C operating range

Supply voltage: 9VDC to 70VDC standard

Supply current :Less than 250mA

Housing rating: Weatherproof (IP65)

Display: 20mm (H) x 6 digits LCD extended temperature range. Plain message prompting

Backlight: LED fibre optic

Warranty: 12 months on instrument and sensors

Fitting time: Typically two hours

Recalibration: Six monthly (recommended) 12 monthly (standard)

Approvals:

-C-Tick

-E-Approved

Fields:

-Weight

-Date

-Time

Printer (optional): 60mm plain paper

Characters: 20 per line

Supply:

-12VDC

-16 to 60v with optional adapter

Current:

-200mA standby

-1A peak printing

Fields:

-Weight

-Date

-Time

-Gross weight

Facebook

Facebook Twitter

Twitter

Email

Email

Print

Print