AWE Group

Conical Ribbon Mixer consists of a transmission device, taper cylinder, outer ribbon mixer, inner reverse screw mixer and discharge valve. It is a new design for viscosity material. The material circles and rises under the operation of the outer ribbon mixer, while the inner reverse screw presses down the material along the shaft, which finishes the mixing. 1. Standard features a. Volume 100-15000L b. Stainless steel or carbon steel c. Ribbon screw agitator for bottom discharge d. Designed for normal temperature and normal atmospheric pressure e. Feed nozzle f. Dust nozzle g. Manuall...

NSW - Delivers Nationally

Conical screw mixer is a highly efficient and low-energy consumption vertical mixer for powder and granule mixing applications. Various particle size materials can be mixed in the conical screw mixer. Key Features Optimal mixing homogeneity Short mixing time Excellent reproducibility of batch production Minimum wear and low maintenance Easy access to mixer Easy to cleaning Excellent mixing at any product level Low power More reasons to choose a Conical Screw Mixer 1.Conical screw mixer is applicable to diverse industries such as pigment, dye, pharmaceuticals, chemical, food, cosmetic...

NSW - Delivers Nationally

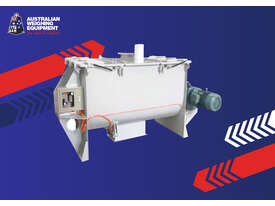

The Ribbon Mixer is ideal for blending powder granular ingredients of similar size, shape density, although gas and liquid streams can also be added. If you re mixing free-flowing solids or slurries of similiar size density, then the Ribbon mixer would be the best solution. The Ribbon Mixer can be configured, for either batch or continuous mixing. They come in sizes ranging from 100- to 20,000-litre working capacity. Choppers can be added, when blending liquids or pastes and dispersing small ingredients. Stainless Steel Ribbon Mixers are mainly used in the food industry, where bulk m...

NSW - Delivers Nationally